M. Sc. Sebastian Peveling

Development and Optimization of Regenerators with Axially Varying Matrix Structures

This project aims to increase the efficiency of regenerative (gas) cycles by developing and optimizing regenerators with axially varying matrix structures. Therefore, analytical and numerical models are applied to the design and the optimization of such regenerators, the performance of which is experimentally investigated afterwards.

Description

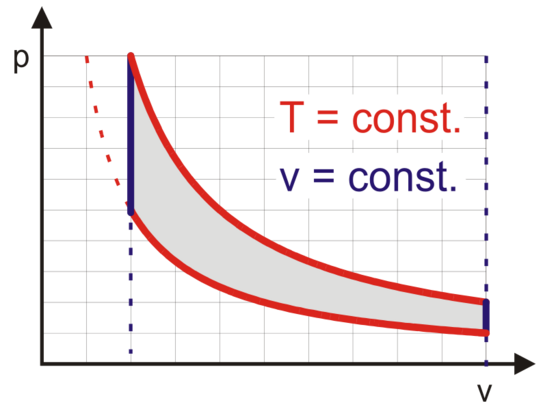

In the course of the energy revolution, concepts for combined heat and power (CHP) systems are gaining in importance. Regenerative gas cycles, the name of which refers to the regenerator as their central component and the main reason for their efficiency, are one option for the realization of such systems. The ideal Stirling cycle, as an example of a regenerative gas cycle, consists of two isothermal and two isochoric changes of state. The heat rejected or absorbed during the isochoric changes of state, respectively, is internally stored in the regenerator, so that the only external heat exchange takes place during the isothermal changes of state. As a result, the ideal Stirling cycle including perfect regeneration reaches Carnot efficiency. [1]

Well-designed regenerators achieve regenerator efficiencies above 90%, but due to the heat flow transferred between matrix and working gas being many times larger than the net heat flow of the ideal process, the remaining losses have a big impact on the performance of the entire cycle. For this reason, even small improvements of the regenerator efficiency have a significant effect. [2]. The fluid properties of the working gas as well as the amplitude and phasing of the mass and volume flow differ between the ends of the regenerator because of the temperature change along the regenerator and the buffer effect of its void volume. As a result, the Reynolds number decreases in the axial direction towards the hot end in common regenerators with a constant structure, affecting both the heat transfer conditions and the pressure losses. The potential of regenerators with axially varying matrix structure accounting for the aforementioned effect has been demonstrated by simulations and few experimental investigations of Stirling and pulse tube cryocoolers in the past [3]. Therefore, this design approach for regenerators is investigated and optimized to increase the efficiency of regenerative gas cycles operating at around/above ambient temperature, i. e. thermal engines and heat pumps.

References

| [1] | Walker, G: “Stirling Cycle Machines” Clarendon Press, Oxford 1973 |

| [2] | Kühl, H.-D.: “Wärmetransformationsprozesse ohne Phasenumwandlung - thermodynamische Konzeption, Auslegung und Optimierung an Beispielen aus der Wärmepumpen- und Kältetechnik“ Postdoctoral Thesis, TU Dortmund University, 2013 |

| [3] | K.Kumar V.V., B. T. Kuhiveli: “Performance Enhancement of a Miniature Stirling Cryocooler with a multi mesh regenerator design” Journal of Engineering Science and Technology, Vol. 12, 2017 |