Reactive Extraction of Hydrophilic Products from Biocatalytic Origin

The development of innovative downstream processing concepts for biocatalytic products serving as building blocks in the chemical and biochemical industry has become increasingly important in the last years, especially due to the increasing prices of fossil resources as well as high costs associated to state-of-the-art workup strategies [1]. In the frame of this work, reactive extraction (RE) of bio-based dicarboxylic acids and diamines is investigated in order to enable selective and cost-efficient downstream processing of these products.

Description

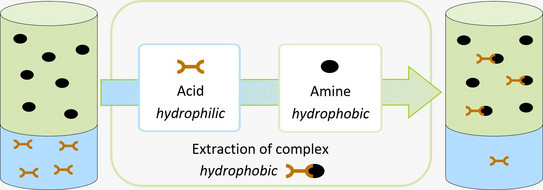

RE combines the beneficial attributes of both, a reaction and a liquid-liquid extraction step, in one single unit operation. It is therefore suited to overcome challenges in downstream processing of fermentation broths including the low concentration of the product in the complex reaction mixture. [2]

Dicarboxylic acids and diamines are platform chemicals, which are of use as building blocks in the bio-based production of polymers such as polyamides [3]. State-of-the-art recovery from fermentation broth includes multiple crystallization steps resulting in high downstreaming costs [4]. Thus, RE is a viable alternative to overcome this bottleneck and to enable the recovery of dicarboxylic acids and diamines without the extraction of byproducts or impurities [5]. In the frame of this work, RE is applied to the recovery of biocatalytically produced dicarboxylic acids and diamines via the formation of a complex between acid and amine. Furthermore, the phase behavior of the RE system will be modeled using the Perturbed-Chain Statistical Associating Fluid Theory (PC-SAFT) reducing experimental effort in the development of RE strategies for the purification of biocatalytic products.

References

| [1] | C. S. López-Garzón, A. J. J. Straathof: "Recovery of carboxylic acids produced by fermentation" Biotechnology Advances, vol. 32, pp. 873-904, 2014 |

| [2] | A. Stankiewicz: "Reactive separations for process intensification: an industrial perspective" Chemical Engineering and Processing, vol. 42, pp. 137-144, 2003 |

| [3] | S. Kind, C. Wittmann: "Bio-based production of the platform chemical 1,5-diaminopentane" Applied Microbiology and Biotechnolology, vol. 91, pp. 1287-1296, 2011 |

| [4] | T. Willke, K.-D. Vorlop: "Biotechnological production of itaconic acid" Applied Microbiology and Biotechnolology, vol. 56, pp. 289-295, 2001 |

| [5] | J. Gorden, E. Geiser, N. Wierckx, L. M. Blank, T. Zeiner, C. Brandenbusch: "Integrated process development of a reactive extraction concept for itaconic acid and application to a real fermentation broth" Engineering in Life Sciences, vol. 17, pp. 809-816, 2017 |