Direct Generation of Compressed Air from Waste Heat by Reciprocating Thermocompressors

This project aims at the development of a multi-stage reciprocating thermocompressor to generate compressed air from thermal sources, preferably waste heat. In this context, analytical and numerical modelling as well as constructive considerations are required to develop a practically and economically competitive solution.

Description

Compressed air is one of the most important and also the presumably most expensive technical energy source, generation of which requires about 16 TWh per year in Germany - roughly 7% of the industrial electricity consumption. Due to various conversion and transmission losses, the overall efficiency from the generation to the final consumption typically amounts to about 5% only. So, substantial savings can be achieved under economical aspects as well as with regard to resource protection and reduction of emissions, if the conventional generation of compressed air by electrically driven compressors is - even just partially - substituted by other techniques featuring a reduced or possibly zero primary energy consumption.

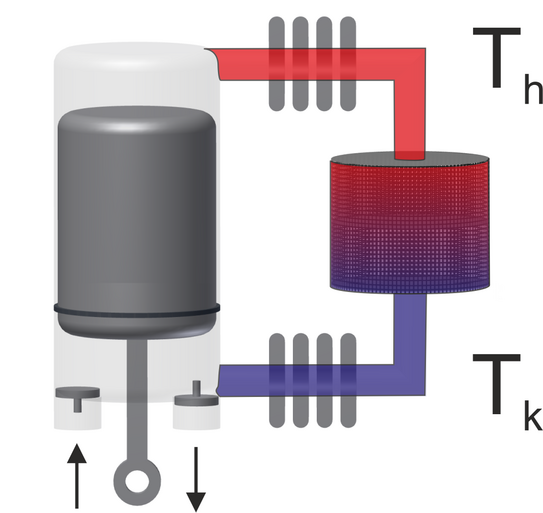

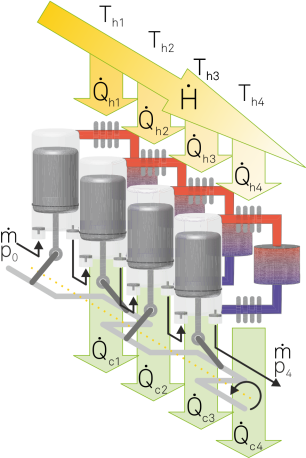

For this purpose, a cascade of so-called reciprocating thermocompressors shall be investigated, first theoretically and also experimentally thereafter. Thus, compressed air may be generated from a heat flow (preferably waste heat) without any detours via electrical or mechanical energy and therefore very directly and efficiently. Basically, the underlying principle of thermal compression is well-known from the Stirling cycle since a long time and was patented in the US as "Bush thermocompressor" in 1935 already, but has only been explored for some low-pressure niche applications so far. It is most advantageously realized by double-acting displacer pistons moving the gas back and forth between a "hot" and a "cold" cylinder volume via a regenerator (and thus reversibly in the ideal case) at a constant overall volume.

According to recent findings there is apparently an option to compose a cascade of thermocompressors from structurally identical and therefore economically producible units, although the state variables of air vary considerably between the initial and the final pressure. The number of units may be adjusted according to the required quantity and pressure level of the compressed air, and their construction may be further simplified advantageously.

References

| [1] | Bush, V.: “Apparatus for Compressing Gases” US Patent2.157.229, 1935 |

| [2] | Glassford, A. P. M.: “Adiabatic Cycle Analysis for the Valved Thermal Compressor” Geliotekhnika/Applied Solar Energy, vol. 13(3), pp.9-14, 1977 |

| [3] | Kornhauser, A. A.: “Analysis of an Idealized Stirling Thermocompressor” Proc. 31st IECEC, Washington, D.C., pp.1331-1336, 1996 |

| [4] | Kühl, H.-D.: “Wärmetransformationsprozesse ohne Phasenumwandlung - thermodynamische Konzeption, Auslegung und Optimierung an Beispielen aus der Wärmepumpen- und Kältetechnik” Postdoctoral Thesis, TU Dortmund University, 2003 |